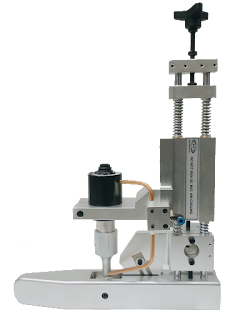

Manual Ultrasonic Cutter | Ultrasonic Fabrics Cutter | Cutting Machine

With our ultrasonic sealing machine & cutting machine, we are able to separate precisely and expeditiously, and weld edges in a refined and reliable way. The principal advantage of the ultrasonic seal and cut method is that the edge of the textile material, while being cut simultaneously, is sealed by the dissipation of ultrasonic energy, thereby preventing the presence of a frayed edge or the unraveling of threads, no discoloration of fabric and very strong, uniform, smooth, clean and long-lasting edges without over thickness with low energy consumption.

The ultrasonic sealing machine system is designed with an AC induction motor, roller, electronic control & working table and is being developed for sealing Fabrics, Plastic Films, Laminated paper, Non-Woven Fabrics, Filters, etc. It is a versatile machine offered in a range of frequencies and power. Typical applications for the systems include protective garments, disposable hospital gowns, shoe covers, face masks, infant nursery garments, filters, bags, curtains, sails, and web splicing. Sealed edges and seams with no stitch holes prevent penetration of chemicals, liquids, bloodborne, pathogens, or particulate thus providing a benefit over conventional stitching methods.

Comments

Post a Comment