WELDING OF THE AUTOMOTIVE COMPONENT PARTS

The Task

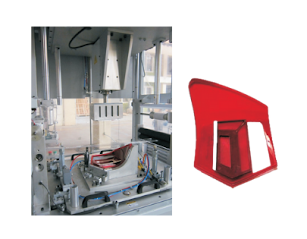

To design an ultrasonic plastic welding system to weld the tail light assembly.

The Solution

In this case, the task was completed by designing a system having a special quick tool changing mechanism (cassette type), a winder-unwinder arrangement to locate the item which is to be welded and a dedicated horn-fixture arrangement to weld the tail light assembly.

The Advantages

- Very short tool change over time

- Short cycle time

- Strong welds

- No damage cause to the surface finish

Comments

Post a Comment